Copromec Electronics

Safety

SAFETY MEASURES

Old construction machinery has flaws in its safety systems. Copromec Electronics designs and implements modifications on machines that don't fulfill the current security measures (presses, extrusion lines, furnaces, automatic lines). These are the most frequent issues:

- lack of risk analysis, lack of certification, high risk environment for the workers;

- SIL not adequate for the machinery being used (eg. SIL 1-2 must upgrade to SIL 3);

- insufficient mechanical protection (gates, electronic barriers, etc);

- slow production to compensate the lack of safety.

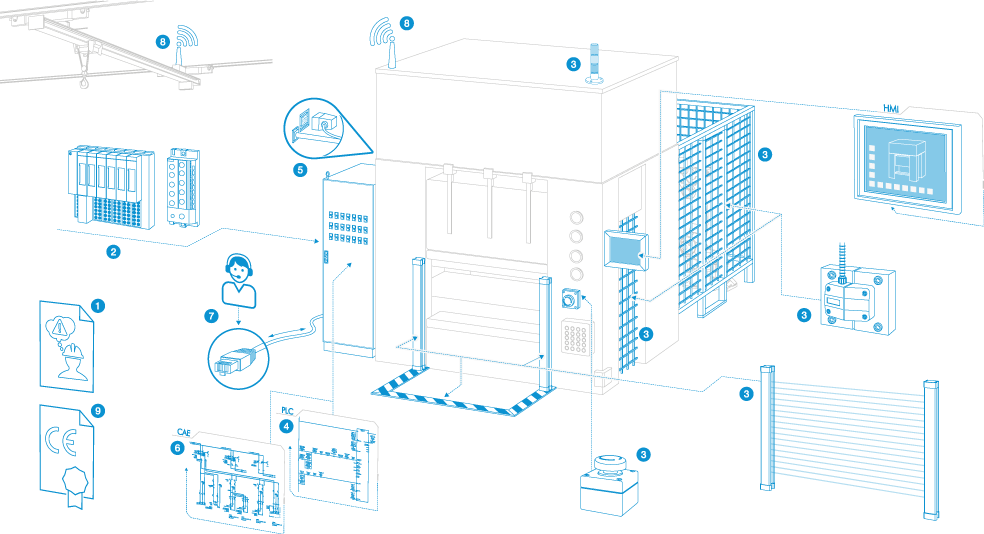

THE APPLICATION

- 1 The application explores the risk and calculates the correct Safety Integrity Level (SIL).

- 2 Deploy safety PLC up to SIL3 with on-line management of certified components.

- 3 Introduction of instruments, guards and safety barriers.

- 4 Development of the safety software project which meets the SIL standard to improve the speed of production and maintenance (eg. slow motion controlled).

- 5 Remake of the electrical wiring that doesn't satisfy the safety measures.

- 6 The electrical / pneumatic product fulfills the appropriate current Safety Integrity Level.

- 7 Assistance and helpline 24 hours.

- 8 Introduction of interfaces for wireless communication with mobile carts or crane bridges, for the purposes of providing safety to the operator in case of access to common areas.

- 9 Supply of the certification of reconditioned machinery.